PTFE catheter liner, also known as Polytetrafluoroethylene tubing, is a high-performance polymer designed to enhance the functionality of guiding catheters. Its low friction coefficient makes it an ideal material for catheter linings, facilitating the smooth passage of other medical equipment through the catheter.

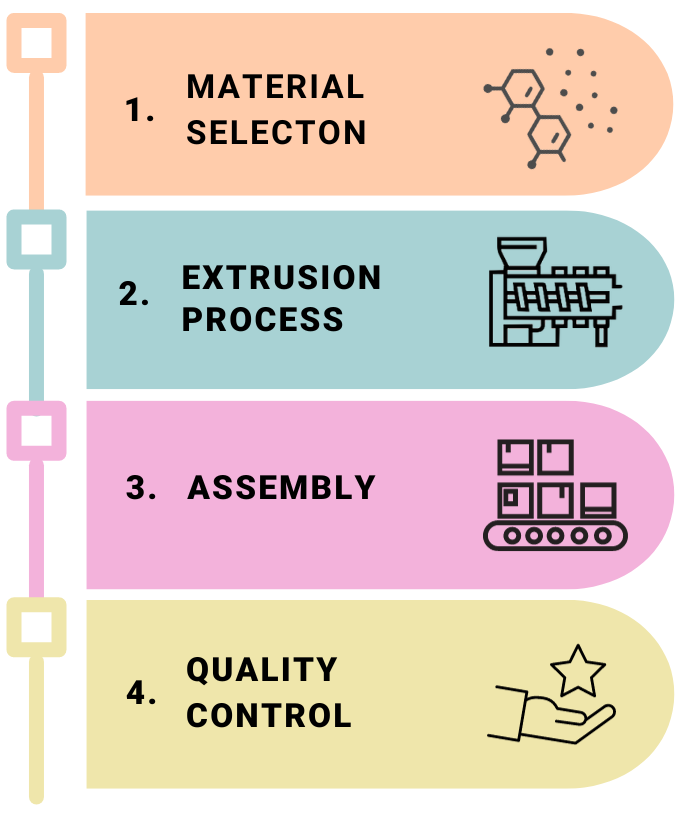

Manufacturing Process of PTFE Lined Catheters

i. Material Selection

PTFE extruded guide catheters is produced after careful selection of high-quality PTFE to manufacture the component. This material is chosen for its suitable properties as liners, including reduced friction, chemical resistance, and temperature resistance.

ii. Extrusion Process

During the extrusion process, the selected PTFE is heated and pressed through a die to form a tube. This PTFE tubing is post-processed before assembly with the catheter body. This tube then becomes the catheter's inner lining.

iii. Assembl

The PTFE extruded tubing is then inserted into the catheter body, typically constructed of another flexible material, such as PEBAX, TPU or Nylon and reinforcement metal braidings. Precision is crucial in the assembly process to ensure that the lining fits precisely within the catheter body.

iv. Quality Control

Following the construction of the guide catheter, rigorous quality control examinations are conducted. These tests ensure compliance with medical standards and verify the proper installation of the PTFE lining without any defects.

The small but critical step: PTFE Etching

One might have missed a critical post-extrusion step of PTFE tubing, and it can cause a catastrophic failure of the device if not done properly. PTFE tubing post-processing, or etching, cannot be underestimated due to the sheer implications it has on the clinical outcomes with the use of the complete catheter device. More than just a manufacturing step, the etching step prior to assembly of the PTFE extruded tubing with the catheter body, is important for good clinical outcomes.

PTFE etching is a surface treatment process that involves chemically modifying the surface of PTFE to enhance its adhesive properties or improve its wettability. It is especially essential for PTFE to overcome its inherent non-stick properties and promote adhesion in catheter assembly. Here are several reasons why etching is necessary in PTFE liners:

i. Improved Adhesion

PTFE is known for its exceptional non-stick properties, which can make it challenging for adhesives or coatings to bond effectively to its surface. Etching creates a textured surface with increased surface energy, promoting better adhesion to catheter body.

ii. Surface Activation

Etching activates the surface of the PTFE liner by introducing functional groups. This activation enhances the surface energy and makes it more receptive to bonding with other materials, such as catheter bodies, adhesives or coatings.

iii. Bonding with Other Materials

In certain applications, PTFE liners need to be bonded or coated with other materials, such as metals, polymers, or elastomers. Etching prepares the PTFE surface, enabling a stronger and more durable bond between the PTFE and the additional materials.

iv. Surface Modification for Lubricity

In some medical device applications, etching can be used to modify the surface of the PTFE liner to enhance lubricity. This is particularly valuable in situations where reduced friction is essential for passage of other medical equipment through the catheter.

v. Promoting Wetting

Etching alters the surface properties of PTFE, making it more amenable to wetting by liquids or coatings. This is important in applications where the PTFE liner needs to interact with or contain liquids.

vi. Enhanced Biocompatibility

For conduit applications, etching can improve the biocompatibility of PTFE liners. The modified surface can facilitate better integration with biological tissues or fluids, reducing the risk of adverse reactions.

vii. Surface Roughness Control

Etching allows for precise control over the surface roughness of PTFE liners. This control is important for specific applications where a particular level of roughness is desired for optimal performance.

At the end of the day, it is critical to have an optimal etching protocol for specific applications to ensure good clinical outcomes. The goal is to achieve the desired surface characteristics without compromising the bulk properties of the PTFE material. Speak to us at jMedtech to discuss on the most favourable approach to manufacture your etched PTFE liner. Contact us to learn more.