Hydrophilic coatings are widely used on the surface of vascular interventional devices to improve the biocompatibility of the surface of the interventional device, reduce the touch of intervention, reduce blood disturbance and damage to blood vessels. [1-3] Particles formed in polymer/coating materials can pose a hazard in certain medical applications, such as in angioplasty and gather.

Therefore, the main challenge for the hydrophilic coating industry is to reduce the number of particles released and the movement of particles on the lubricious coating of medical devices after the medical device is inserted into the object [4], which requires a high degree of robustness of the lubricating coating .

Since the development of hydrophilic coatings in 2013, jMedtech has been committed to the development of interventional devices that can be applied to different materials and take into account lubricity and firmness coatings. These products have been widely used in clinical operations. In this article, we will explain the key points of the process of using coating photocuring to treat interventional instruments based on the technical applications summarized over the years.

The lubricity and firmness of the hydrophilic coating are two important indicators for evaluating the function of the coating.

The lubricity of the hydrophilic coating is understood from a microscopic perspective. The functional layer of the coating is combined with water molecules through hydrogen bonds, and the whole becomes swollen, soft and elastic, thereby achieving the lubricating effect; from a macroscopic perspective, the surface of the coating is in contact with Water binding forms a more uniform and smooth hydrogel film surface with a lower coefficient of friction.

The coefficient of friction is an index to evaluate the lubricating performance of the coating. There is no specific standard for the test of the friction coefficient of vascular interventional products. Refer to "YY/T1536-2017 Standard Test Model for Evaluation of Surface Sliding Performance of Non-intravascular Catheters" and combine the characteristics of the device itself. For testing and evaluation, consider the statistics of the sample size, and the coefficient of friction test must be stable and reproducible. The friction test equipment developed by jMedtech far meets the above requirements. It can control the clamping force of the product with high precision, automatically monitor the friction force of the product surface at constant temperature for multiple times, and obtain the friction coefficient curve displayed in real time.

There is currently no standard method to evaluate the fastness of the coating. In the process of product technology adaptation, usually after the friction limit test, the integrity of the coating is observed by Congo red staining to evaluate the fastness of the coating.

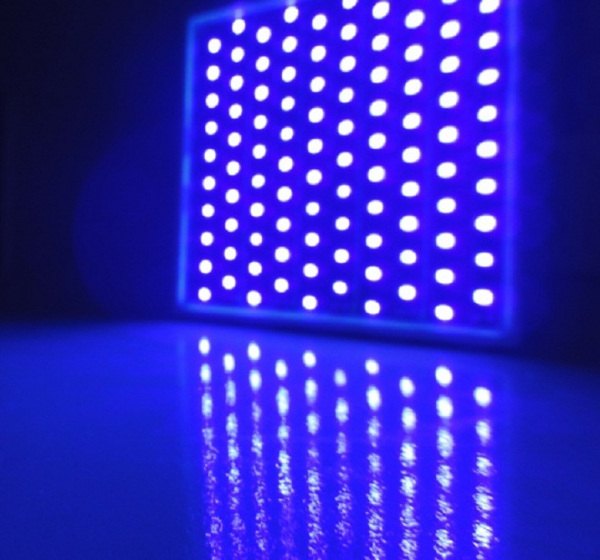

The photocuring coating process refers to the photochemical reaction of the coating liquid containing the polymer matrix on the surface of the product under the irradiation of ultraviolet light to form a functional coating.

Under parallel conditions, the longer the light time, the more fully the active ingredients in the coating solution react. This is because the longer the illumination time, the more fully the effect of the photosensitizer, which is more conducive to the generation of surface free radicals, the more active centers for photoreaction on the surface of the film, the more sufficient the contact between the substrate and the surface of the film, and the higher the degree of chemical connection [5] .

However, with the further extension of the light time, it is not conducive to the photoreaction, because if the light time is too long, a large amount of active ingredients will be homopolymerized, the viscosity of the system will increase, and the heat of polymerization will not be easily dissipated. Moreover, excessive light exposure time will also destroy the structure of the film substrate and cause it to degrade. Reflected in macroscopic applications, the lubricity and coating stability of light-cured products are a pair of mutually restrictive balance.

Therefore, in actual operation, the illumination time should be based on the premise that the substrate structure will not be damaged and the coating will not be thermoplastically deformed due to long-term illumination and heating. After the firmness of the coating can be ensured to the greatest extent, the illumination time should be gradually reduced. After multiple batches of curing, checking the friction of the coating and simulating the integrity of the coating after use, finally obtained a set of data on the light time, friction coefficient, and coating firmness, and concluded that the hydrophilic coating lubricated The balance of sex and firmness.

Combining the above points, we come up with an experimental model: monitor the change of friction force with the test distance to obtain the average value of friction force, and obtain the information of coating lubricity; multiple cycle tests, real-time monitoring of the peak value and average value of coating friction force during the cycle Changes in the coating to obtain information on the firmness of the coating.

We will take Pebax, which is widely used, as an example to illustrate how the light-curing coating process finds the balance between the lubricity and firmness of the hydrophilic coating. Using the hydrophilic super-slip coating, hydrophilic coating equipment and friction tester provided by jMedtech, under the parallel conditions of only changing the light curing time of the functional layer of the coating, the number of friction tests and the average value of friction and Peak change graph.

It can be observed that under the condition of light time of 420s, although the peak value of friction force has no upward trend, the average value of friction force is the largest and the lubrication effect is the worst.

Comparing the light time of 240s and 300s, the average friction force of the coating is smaller at 240s, but when the light time is 330s, the average friction force decreases instead, and there is no upward trend compared with the former two, which reflects the lubricity and coating stability checks and balances.

Under the condition of light time of 330s, the average friction force of the coating is the lowest, and after 75 friction tests, the average value and peak value of friction force have no obvious change, which is the closest to the balance point of the firmness and lubricity of the hydrophilic coating , the sample was stained with Congo red and dried, observed under a microscope, no coating shedding phenomenon.

There are many types and shapes of substrates used in interventional devices, and at the same time, substrates are required to be spliced and mixed while retaining their original performance characteristics. This requires very strict requirements on the applicability and application technology of the coating solution. Therefore, finding the balance between the lubricity and firmness of the hydrophilic coating requires a large amount of experimental data accumulation and rich industry experience.

[1] Mann T, Cubeddu G, Bowen J, Schneider JE, Arrowood M, Newman WN, et al. Stenting in acute coronary syndromes: a comparison of radial versus femoral access sites. J Am Coll Cardiol 1998;32:572-6 .

[2] Murayama Y, Tateshima S, Gonzalez NR, Vinuela F. Matrix and bioabsorbable polymeric coils accelerate healing of intracranial aneurysms: long-term experimental study. Stroke 2003;34:2031-7.

[3] Gaba RC, Ansari SA, Roy SS, Marden FA, Viana MA, Malisch TW. Embolization of intracranial aneurysms with hydrogel-coated coils versus inert platinum coils: effects on packing density, coil length and quantity, procedure performance, cost, length of hospital stay, and durability of therapy. Stroke 2006;37:1443-50.

[4] WO 2008/104572

[5]Xiao Q Y , Liu Z, Zhou J.Research on ultraviolet radiation graft modification of polyethylene hollow fiber membrane [J].Journal of Tianjin Polytechnic University,2005,24(5):49-51